PRODUCT SERIES

PRODUCT SERIES

PRODUCTS

PRODUCTS

Introduction

Introduction

PLHN Series Compact Mixer and Granulator is one of the standard process equipments in the solid

dosage production procedure in pharmaceutical industry, and is also widely used in chemical foodstuff industries, etc…This equipment has functions of mixing and granulation. and it is full compliance with GMP requirement.

Principle

Principle

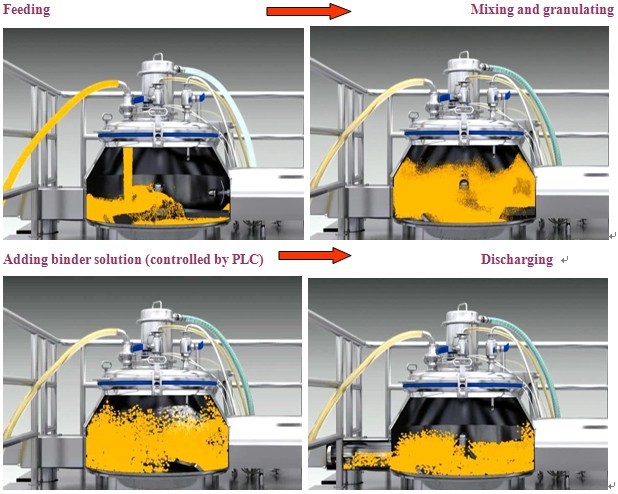

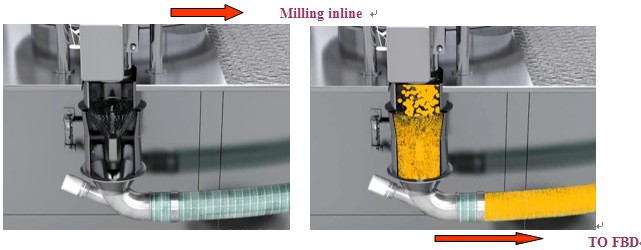

Charge the materials by Pharmacy Lifter or vacuum charging system. start the procedure, under the action of the impeller, materials are set in a multidimensional shear flow state and thoroughly mixed. Then the spray gun system sprays the binder solution into the bowl to agglutinate with the materials and, under the combined action of the impeller and chopper, uniform and porous granules are produced. On finishing the granulation process, granules are discharged through the discharge port to the next process.

Characteristic

Characteristic

This equipment is successfully designed on the basis of a wide research, absorption and digestion of foreign advanced models. The equipment is made of high quality Austenitic stainless steel, all the corners and angles are rounded off using arc transition technique; the whole machine has no dead angle, residue, uneven surfaces or protruded screws. PLC is designed to ensure a fully automatic control. All the operations are automatically finished according to the customer’s set parameters; moreover, process parameters can be printed and records of original data are truthfully reliable. PLHN Series Compact Mixer and Granulator comply entirely with GMP requirements for medicine production.